Selling fast!

Get yours while you can.

Your cart is empty :(

Continue shopping

4xJournal Vol.5

OUT NOW!

Your cart

Estimated total:

$0.00 NZD

FIL-ECO-1

Couldn't load pickup availability

Disclaimer: It is the purchaser’s responsibility to ensure all products and the installation thereof meet current LVV requirements, where applicable.

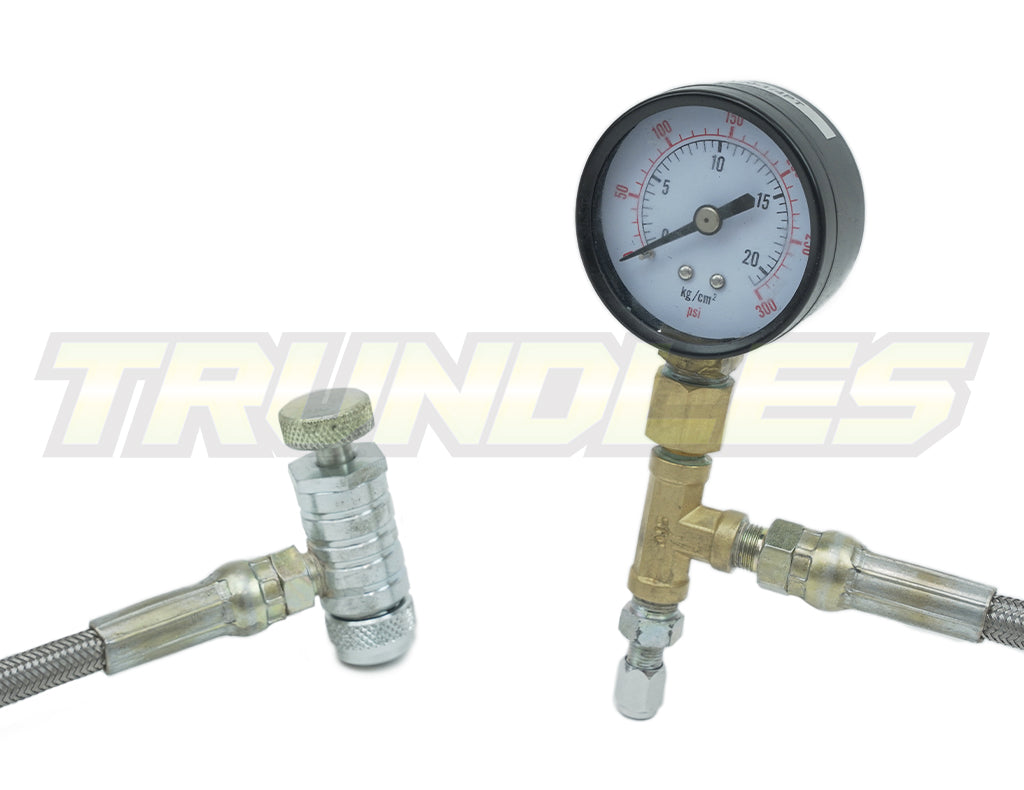

Profender Nitrogen Gas Filler Eco with Hose

Includes:

1x Profender Nitrogen Gas Filler Eco with Hose - FIL-ECO-1

Details:

- Affordable, easy to use nitrogen filler for adjusting the pressure in shock absorbers

- No loss air chuck valve for precise shock charging

- Built in pressure gauge

- 1 metre Teflon braided hose for easy servicing

More Information:

A no loss gauge is essential for correctly recharging nitrogen gas charged shocks after servicing or tuning.

The gauge is simply connected to the gas source and the shock, then the valve is opened and gas is allowed to travel into the shock.

The valve is then closed whilst still under pressure ensuring the shock remains at the correct PSI level.

The Gauge reads to 350 PSI with a simple black on white readout that is easy to read in all conditions.

| Make | Model | Years |

|---|---|---|

| UNIVERSAL | UNIVERSAL |

We're happy to help.

Selling fast!

Get yours while you can.

Trundles and this website are not affiliated with, endorsed by, or associated with Toyota. All trademarks, service marks, and logos used on this website are the property of their respective owners. The mention of Toyota on this website is solely for informational purposes and does not imply any partnership, sponsorship, or affiliation.

Profender Nitrogen Gas Filler Eco with Hose

Includes:

1x Profender Nitrogen Gas Filler Eco with Hose - FIL-ECO-1

Details:

- Affordable, easy to use nitrogen filler for adjusting the pressure in shock absorbers

- No loss air chuck valve for precise shock charging

- Built in pressure gauge

- 1 metre Teflon braided hose for easy servicing

More Information:

A no loss gauge is essential for correctly recharging nitrogen gas charged shocks after servicing or tuning.

The gauge is simply connected to the gas source and the shock, then the valve is opened and gas is allowed to travel into the shock.

The valve is then closed whilst still under pressure ensuring the shock remains at the correct PSI level.

The Gauge reads to 350 PSI with a simple black on white readout that is easy to read in all conditions.